Fan

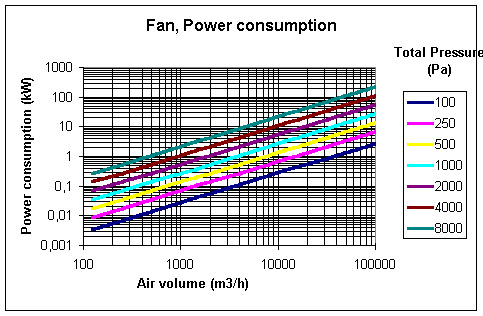

Power Consumption

The ideal power

consumption of a fan (without losses) can be expressed as

Pi = dp q (1)

where

Pi = ideal power

consumption (W)

dp = total pressure

increase in the fan (Pa)

q = air volume flow delivered

by the fan (m3/s)

The ideal power

consumptions for fans at different air volumes and pressure increases are

expressed in the chart below:

Fan Motors and Starting Torques

A fan motor must be capable not only of driving the

fan at operating speed, but also be capable of accelerating the fan wheel to

the operating speed

A fan motor must be capable not only of driving the fan at operating

conditions, but also be capable of accelerating the fan wheel, drive and shaft

to the operating speed. For a fan transporting a large volume of air at low

static pressure the motor power required during the continuous operating

process may not be enough for starting the fan. Often a correct designed and

adjusted motor protection system will stop the fan before the windings are

overheated and insulation damaged.

The motor torque should during design be checked against the fan wheel

torque up to 90% of the synchronized speed.